AUTOMATION TECHNOLOGY

You want to make your production machine even more efficient and are looking for an automation technology specialist? Helmerding hiw Maschinen GmbH is your competent supplier/partner for loading and unloading, automated part transfer as well as the packaging of products. We implement customized solutions, i.e. container and pallet transport (development of specialized containers and pallets on request), component handling via linear systems and industrial robots. In combination with our press portfolio you will receiver a complete solution from a single source.

PLANT INFORMATION

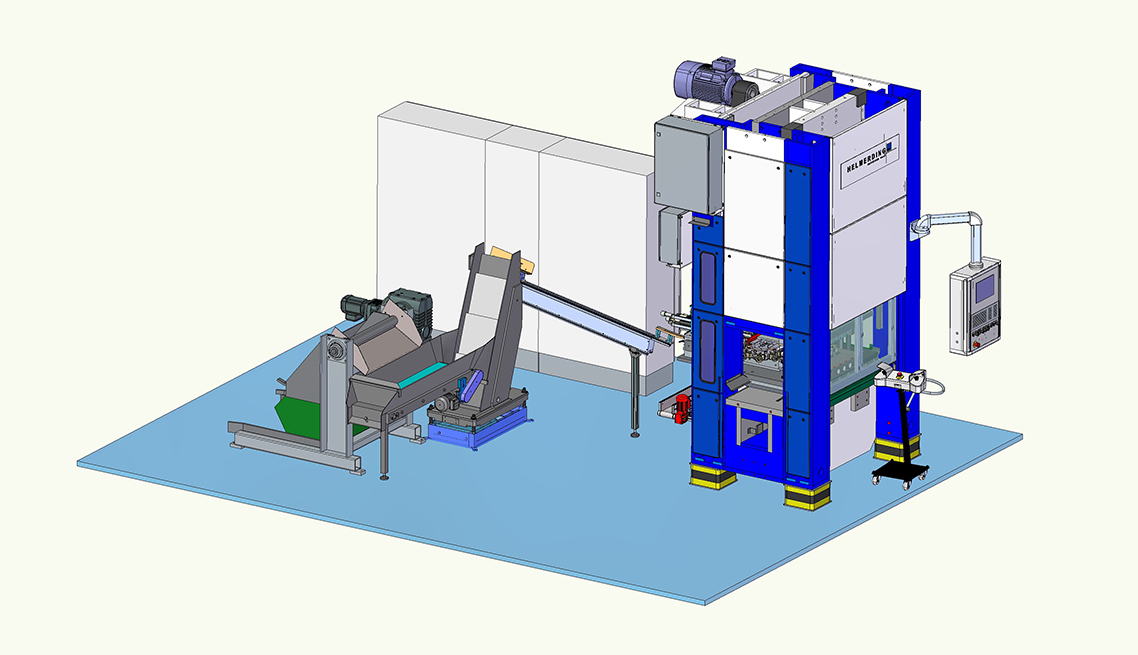

- various configurations (setup process simple and fast)

- Performance: 80 strokes/min

- Press 125 to

- Implementation in compact design with taktomat inside the press

- Separation of contact-blanks made from bulk material via 1 universal feeding technology (incl. GLT tipping unit)

- Insert into workpiece holders via highly dynamic servo linear drives

- Forming using a 3-step tool

- Checking the quality features via camera system

- Delivery of finished parts via belt conveyor

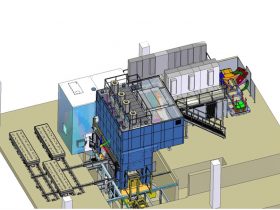

- Direct linking of 2 Helmerding presses (SDH 250 / KDH 1200) in an L-shaped arrangement

- Variants Æ 50 – 550 mm

- Output: 80 strokes / min

- Unwind tape material using the Helmerding decoiler HE-12 (12 to, Æ up to 2000 mm, movable with loading chair)

- Smoothing of the material using the R70 straightener

- Belt loop bridge (lifting table with roller conveyor)

- Servo-motorized roll feed unit EWH 800

- Roller lubricator for 2 media

- Cutting servo press 250 to (setup process / tool change via tool change system WZW 2)

- Servo-motorized removal handling (central adjustment of the guides to product variants, compensation of the height level to the transfer press)

Scrap shears for shredding the remaining material strip (longitudinal and cross cutting) - Underground scrap / waste disposal via conveyor belts with link chain belts to the central trough

- Transfer pull servo press 1200 to (set-up process / tool change via tool trolley, 30 to)

- Servo motor 3-axis transfer, feed 0.5 to 600 mm with special optimization of the movements between transfer and tool

- Removal of the finished parts via belt

- Incl. Storage of the products in internal transport containers or KLTs and stacking on Euro pallets, structure in line form

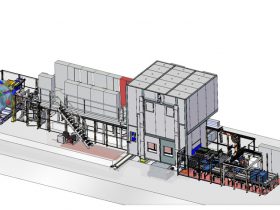

- 2 very different variants

- Output: 60 strokes / min (1 variant double falling)

- Unwind tape material using the Helmerding decoiler HE-16 (16 to, Æ up to 2000 mm movable with loading chair)

- Smoothing of the material using the R-90 straightener

- Belt loop bridge (lifting table with roller conveyor)

- Servomotor roller feeder EWH 600

- Roller lubricator for 1 medium

- Servo press 800 to (set-up process / tandem tool change system via tool trolley, 18 to)

- Soundproof booth

- Removal of the finished parts via belt with guide plates (set-up kit for variants), collecting and buffer section

- Variant 1: Acceptance of a 3-pack of finished parts directly from the belt using a robot

- Variant 2: Collecting in magazine slots, emptying the magazine slots using robots

- Industrial robot for stacking finished parts with multiple gripper systems incl. Spreading strokes

- Pallet and container circulation system for euro pallets and special containers

- Portal robot for depalletizing and palletizing KLTs from / on Euro pallets

COMPETENCE

The basic principle of the Helmerding system development is a module orientation with defined interfaces. This applies to the press, the conveyor system, the transfer as well as to the peripheral system components such as tool changes and robotics.

We guarantee precision and quality through certified business processes and a high proportion of in-house production. The good infrastructure in terms of buildings, processing machines and systems to support our work processes is another quality component.