HELMERDING TRANSFER SYSTEMS

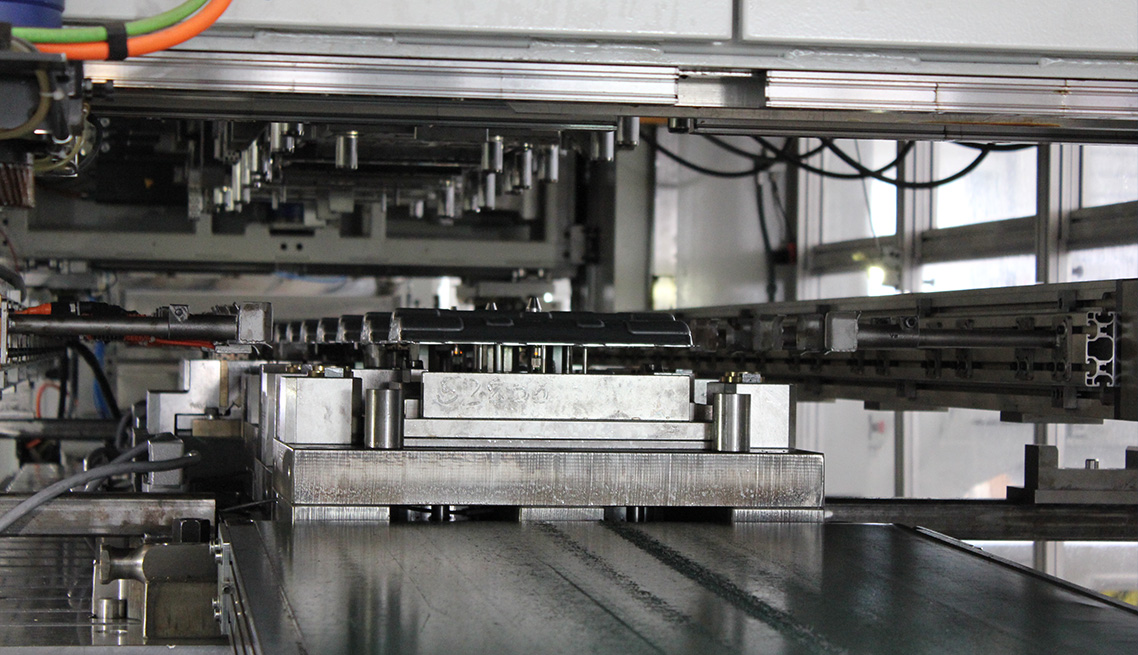

Behind Helmerding’s transfer technology is a customer and requirements-oriented concept. The functional units are of modular design and therefore facilitate the construction of customised systems for any application.

The transportation of parts through the press is achieved using vertically mounted or suspended transfer units, space-saving gripper and lever units, suction cup bridges, active grippers, magnetic and suction tools.

Feeder systems for inserting and turning in presses are part of the scope of delivery.

Helmerding can therefore guarantee optimised and secure transportation through pretensioned and stand-alone presses.

OUR MACHINE PORTFOLIO

We develop double-column presses for different applications. Please do not hesitate to contact us if you have special requirements.

COMPETENCE

The fundamental principle behind the development of Helmerding plants and machines is a modular focus that incorporates defined interfaces. This applies equally to the presses, coil feeding systems, transfer systems and to the peripheral system components such as tool changers and robotics.

Helmerding guarantees precision and quality through certified business processes and by producing a high percentage of components in-house. The good infrastructure in terms of buildings, processing machines and systems for supporting our work processes is a further key quality element.